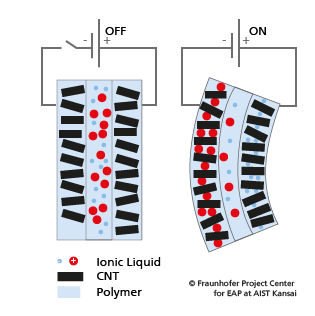

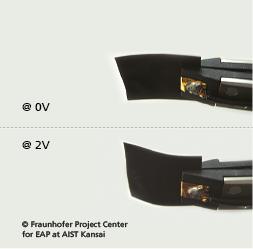

EAP: electroactive polymers are polymers that exhibit a change in size or shape when stimulated by an electric field. A polymer is a large molecule composed of many repeated subunits (monomers). Familiar polymers are e.g. polyethylene (PE) and Polypropylene (PP) which are used in plastic bags or wrap, or polyethelene terephthalate (PET) for plastic bottles. In addition, there are other polymers such as plastics, rubbers, chemical fibers, adhesive, paints, etc.

<Properties>

Typical characteristic properties of a polymer are light-weight, softness, flexiblility and formablity in various forms, which cannot be achieved with metals or ceramics. Based on the similarity of functionality, EAP actuators are often called as artificial muscles.

<Applications>

The most common applications of these materials are actuators and sensors. As the demand for sensors should reach over one trillion units between 2017 and 2022*1 due to penetrating the IoT (internet of things), the needs for EAP materials should also rise correspondingly. In addition, medical applications, biomimetics and robotics, energy harvesting and storage devices etc. are counted as further examples of EAP applications.

*1: estimated by machine and device makers such as Hewlett-Packard, Intel, Robert Bosch and Texas Instruments

FPC AIST

FPC AIST